It’s Alive!

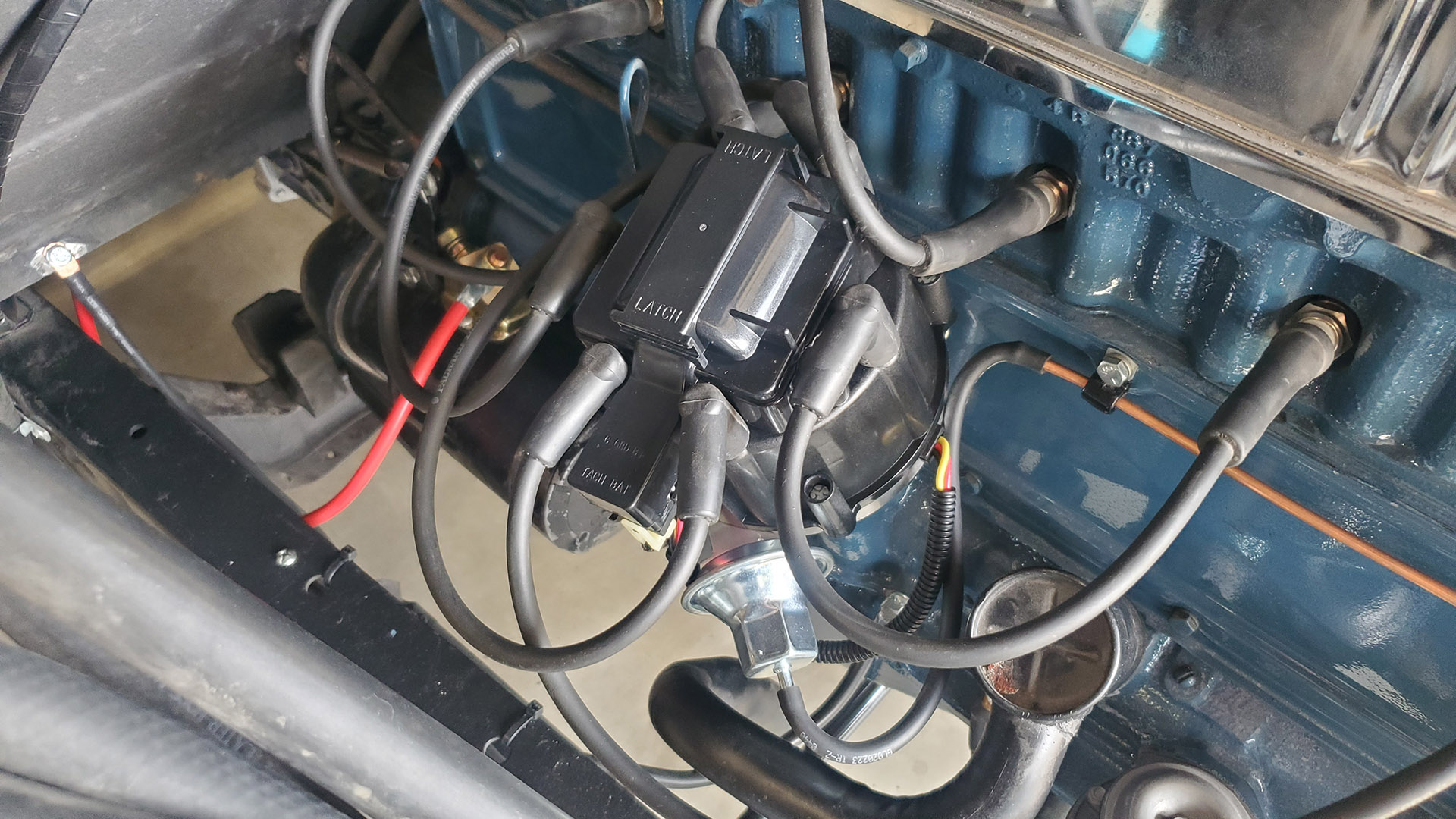

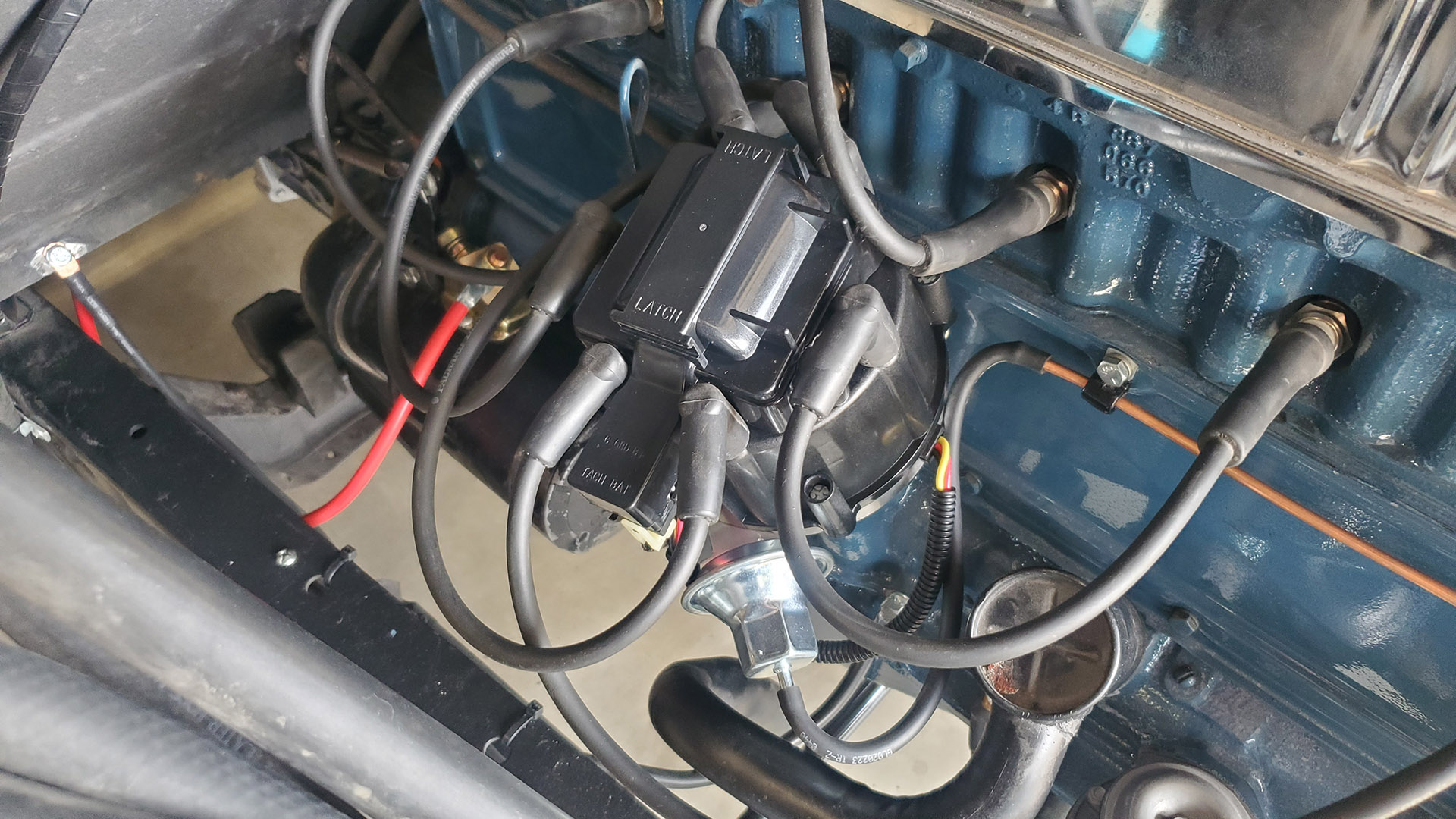

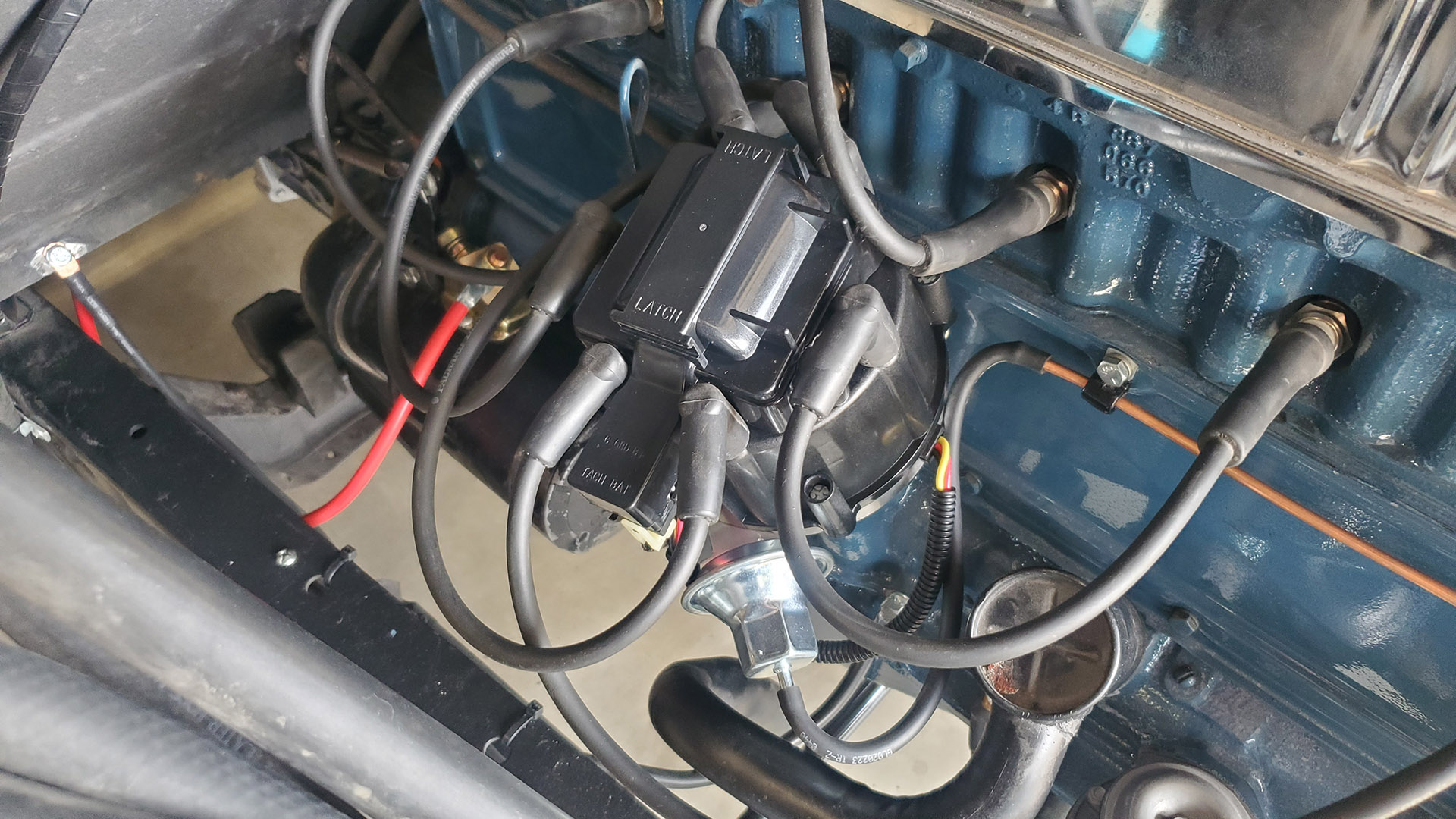

In our last post our ignition system died. The ignition control module from the '80's and companion distributor gave up the ghost. Rather that waste more time and money on it, I decided to upgrade to a more modern HEI system. Amazon offers a kit from A-Team Performance that fits the ol' Chevy 235. Unlike the 'old' electronic ignition setup, this has the coil integrated into the cap.

A-Team. It's got to be good, right? Yeah, we'll see. It was pretty cheap. But, by golly, it showed up quickly and after dropping it into the motor it fired right up. So, that's a win for now!

Now that we know the engine starts and runs it needed to be tuned into submission. For that I set the radiator up on some blocks, made the connections, and filled it with water. Jumper wires fed the electric fan to make sure it comes on with the temperature switch we relocated to our water neck.

I started her up again and brought it up to temperature. The fan kicked on like it should. At the same time I used a timing light to set the ignition timing to the factory 5 degrees before top dead center. The distributor is rotated until the marks are aligned and the distributor locked down.

With more than one carburetor, they need to be synchronized. Basically the throttle plates need to be open the same amount so that each carb delivers roughly the same amount of air and fuel to the engine.

For that I used a Uni-Syn tool. You place it over the carb air horn and a little bead gets drawn up into a sight glass. The more open the throttle, the higher the bead is drawn with vacuum. When the bead is drawn to the same height on each carb, they're adjusted the same or 'synchronized'.

The tool was little borderline on this engine and carb setup. I had to adjust the tool to choke it down enough to draw the bead up in the sight tube just a little ways. and with the tool choked, so was the engine. Should be pretty close though. There's a lot of fiddling. Adjust, tweak, check - back and forth. Up and down on idle RPM.

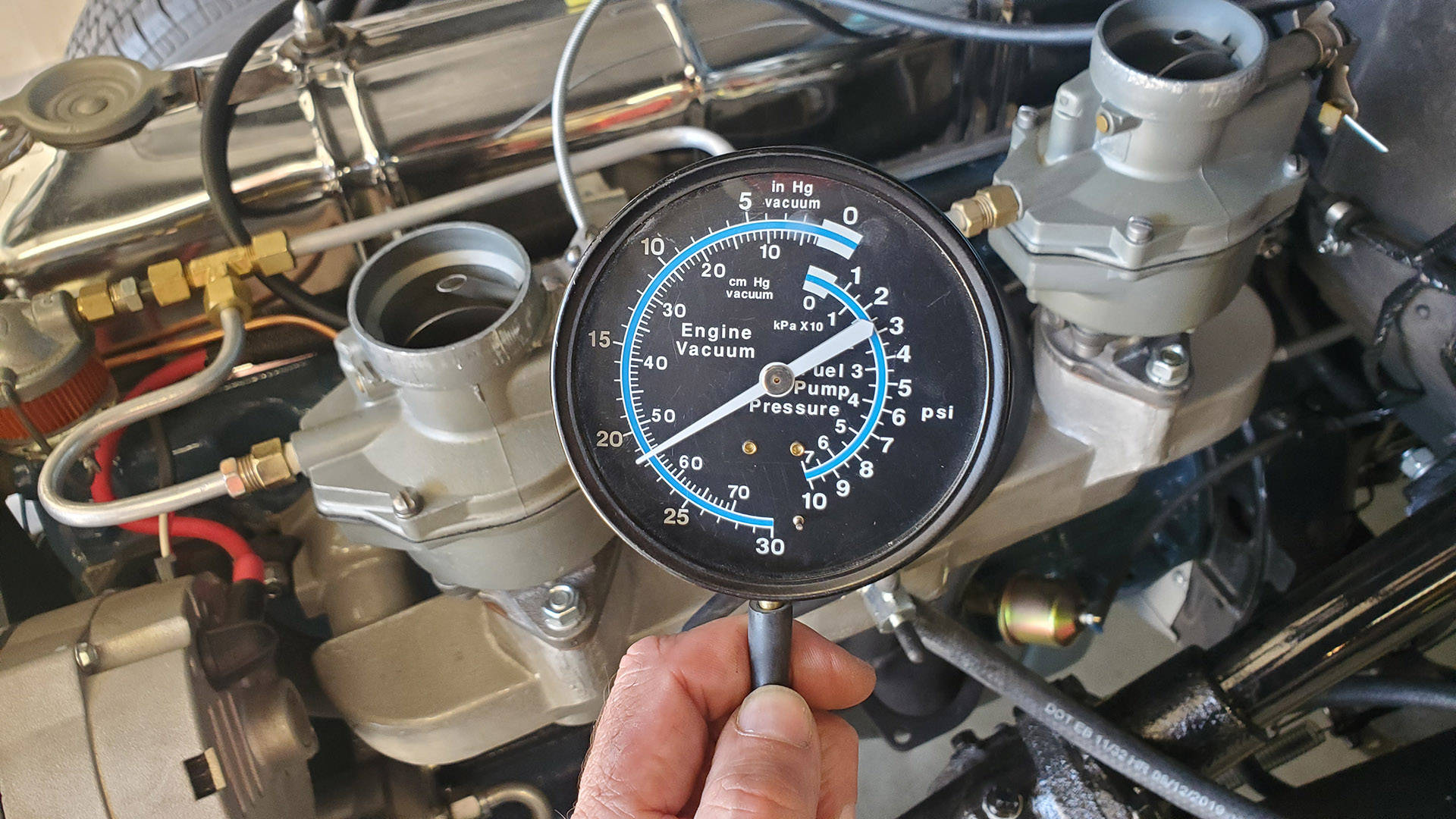

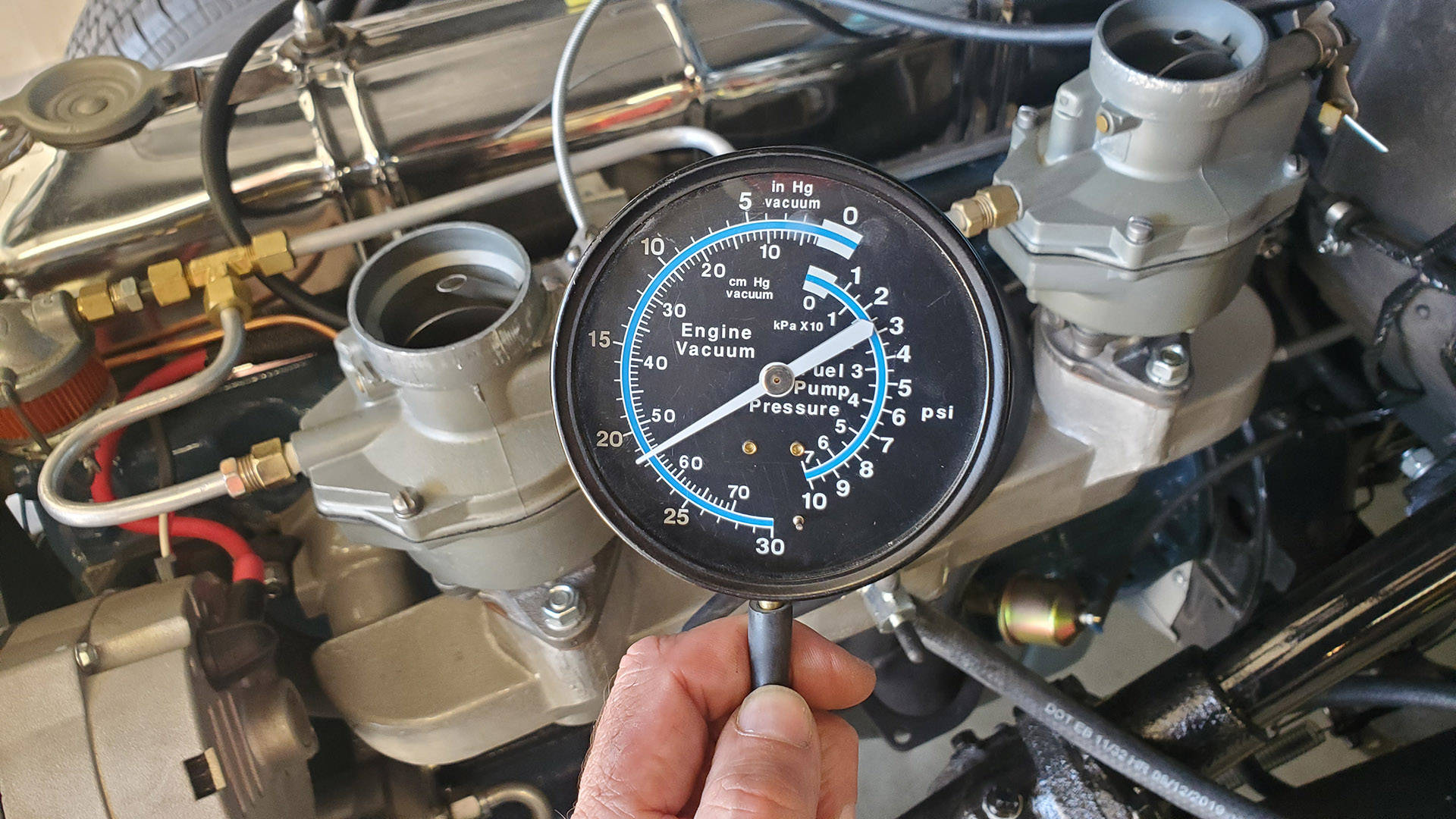

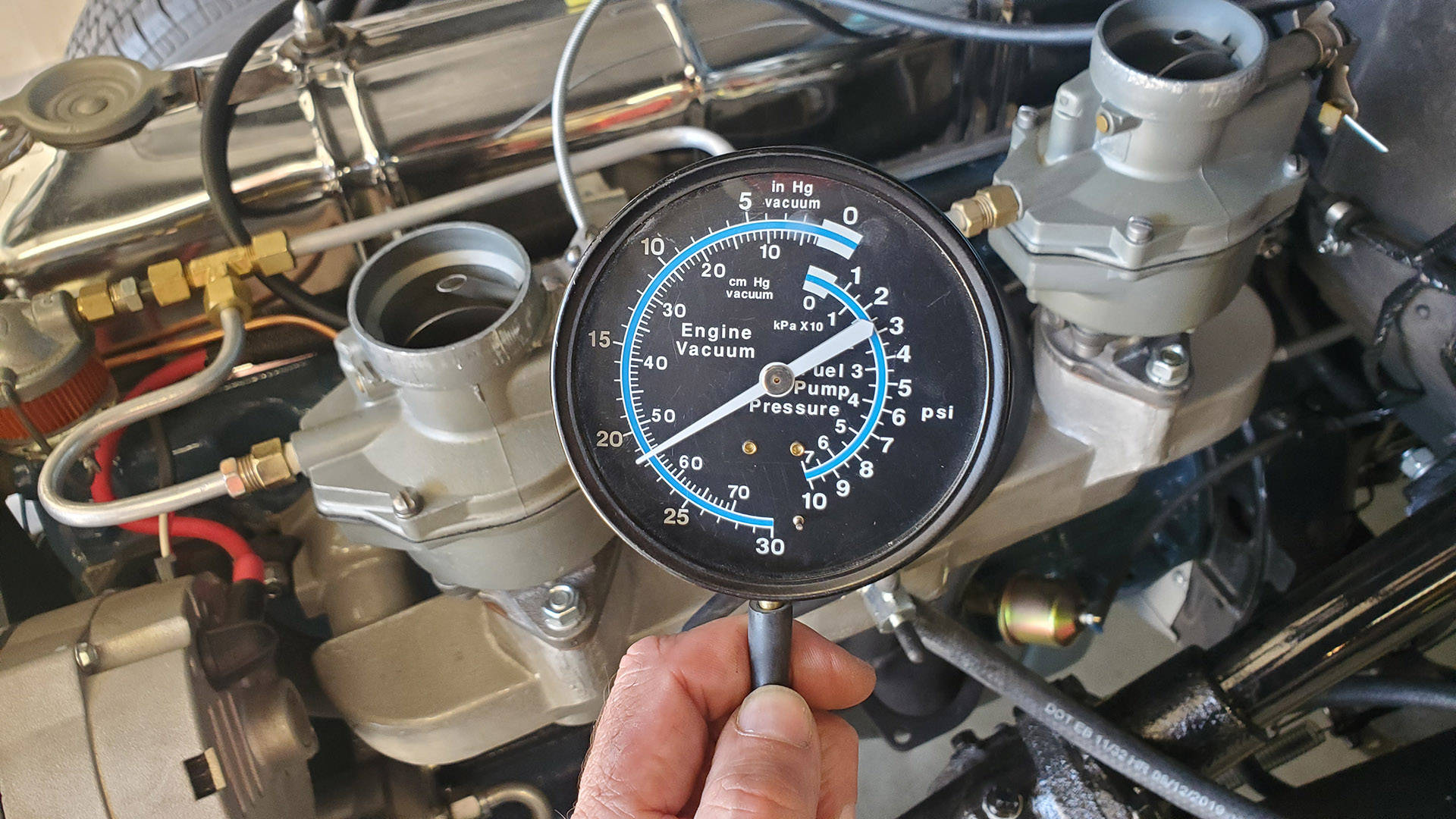

The original 216 engine with a single carburetor was spec'd to idle around 500 rpm. This one seems happier at around 750 rpm. An earlier compression test showed one cylinder (#4) that was quite low compared to the others. Engine vacuum while running is at or above specs - so that's good.

As luck would have it, the ignition switch failed again (unrelated to the distributor). This is the second one from the same vendor to fail internally in the same way - a plastic piece literally breaking inside. When it breaks, the key will not turn it on or off. No doubt it's made overseas like so many other reproduction parts. The quality and reliability just isn't there.

The original GM Delco Remy ignition switch was kinda falling apart when I took it out. That's the only reason I decided to replace it. Unfortunately, for me, the replacements have been junk. I did some repairs to the original and reinstalled it in the dash. It works and 'feels' much better when you turn the key. I'm not sure how long it will last but at this point I have no doubt it will outlast the copies.

The next task will be to hook up the dual throttle linkage and make sure it works properly. Then we'll get the truck off the wheel dollies and see if it will move on it's own. If so, we'll work on transporting it to the exhaust shop.